Tests

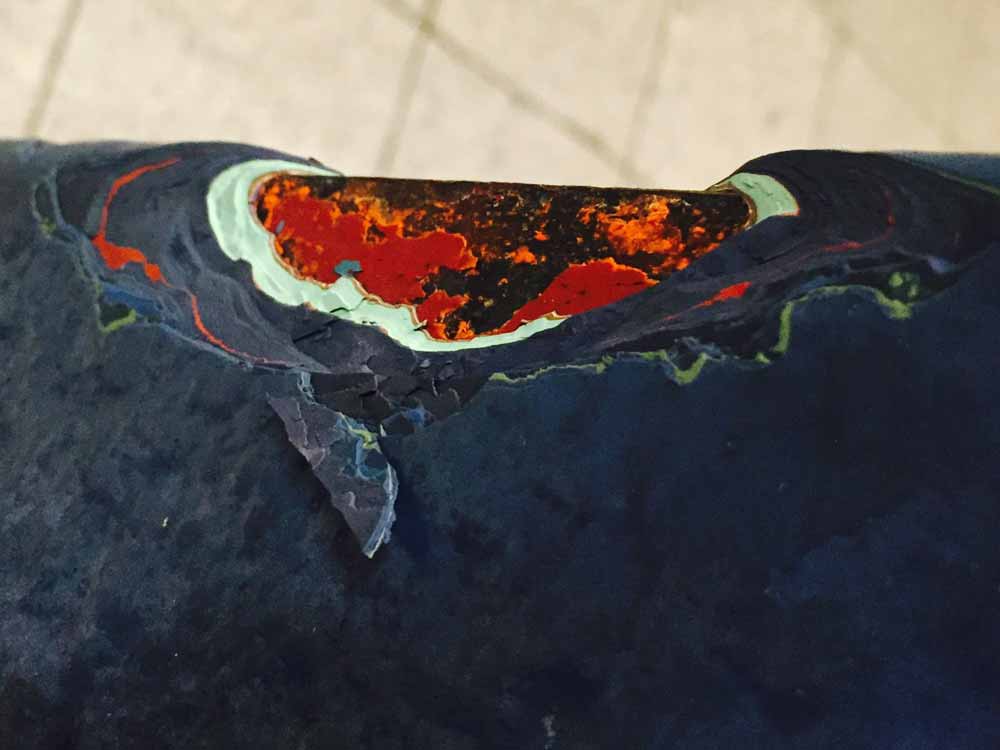

Coating surveyors can perform various tests on both the structure itself (field tests) and on paint samples collected for laboratory analysis.

On-site testing primarily involves physical tests and some basic chemical determinations. There are several techniques available for conducting these tests, including tests for water-soluble salts, solvent rub tests to assess the cure of epoxy and zinc silicate coatings, solvent tests to distinguish between convertible and non-convertible coatings, tests for amine bloom/blush, adhesion tests, pinhole/holiday detection, gloss measurement, surface profile assessment, dust testing, abrasive tests, pH testing, blast pressure testing, blotter tests, environmental tests, wet and dry film thickness measurement, examination under a microscope, and hardness testing.

When it comes to analysing coating condition or investigating coating failures, there are numerous analytical techniques available. The choice of technique largely depends on the substance being analysed and the specific information required.

However, it is beneficial to have discussions with the analyst when submitting samples for analysis. These discussions can help familiarise the analyst with the nature of the samples and provide insights from the surveyor regarding potential reasons for the coating failure or recommendations for maintenance. This information can assist in determining the most appropriate analytical techniques to use and ensure the results are correctly interpreted.

The Coatings Radar has been created to facilitate field testing and laboratory testing procedures. Field testing includes the utilisation of specific standards, while laboratory testing encompasses various techniques such as optical microscopy, scanning electron microscopy (SEM), SEM coupled with energy dispersive X-ray spectroscopy (SEM-EDS), Fourier transform infrared spectroscopy (FTIR), gas liquid chromatography-mass spectrometry (GC-MS), ion chromatography, and differential scanning calorimetry.